BIO

About Scott Baxendale

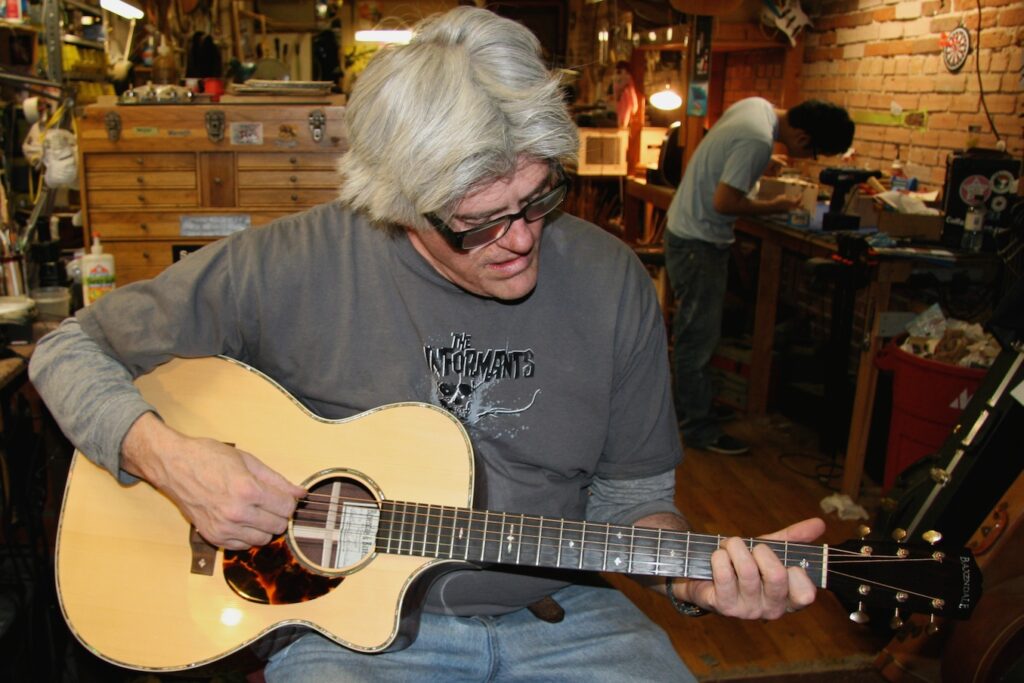

With over 50 years of professional luthier experience building and restoring guitars and other fretted instruments Scott Baxendale is sharing his vast experience, knowledge and skills to a new generation of aspiring luthiers.

Three years ago Scott Baxendale moved his full service luthier shop, Baxendale Guitars, to Santa Fe, N.M. From Athens Georgia and has now reached the final phase of his career before retiring from the Luthier business. Scott has decided spend these next few years teaching his luthier skills and guitar design knowledge to the next generation of Luthiers.

This is a golden opportunity for any aspiring luthier who wants to build a career in the business of guitar restoration and guitar making.

Scott began his luthier career when he left the University of Kansas in 1974 and went to work for Stuart Mossman at Mossman Guitars in Winfield Kansas. Mossman guitars are well known and sought after in the Bluegrass community. Winfield is home to the Walnut Valley Festival which holds the National Flatpicking Championships every September in Winfield KS.

Scott soon rose to the top at Mossman guitars first becoming the foreman of the finish department and later in charge of final assembly, QC and set ups. It was here where Scott learned and mastered the basic skills of guitar making.

In 1977 Scott moved to Kansas City and worked for Swift Music Repair which was a wholesale repair business servicing the school bands and orchestras in the KC area. There we did general repairs and restorations as well as service the orchestral instruments from all the schools in the area. Scott began building his custom guitars during this time.

In 1978 Scott went to work for Gruhn Guitars in Nashville. Here we specialized in restoring vintage instruments. It was here during the late 70’s and early 80’s where Scott designed his proprietary tuned scalloped top bracing design after researching, restoring and inspecting many pre-WW2 guitars which are considered the best acoustic guitars ever made. Gruhn Guitars always has a vast wealth of these vintage instruments to inspect and learn from which allowed Scott to study the differences and come up with his bracing design which has slowly evolved and been improved upon since the late 70’s.

In 1982 Scott returned to Winfield Kansas and helped Stuart Mossman finish some of the last guitars he was building at the time. Scott showed Stuart his top bracing design and Stuart was so impressed by the sound that he built his last batch of guitars with Scott’s top bracing design.

In 1985 Scott purchased Mossman Guitars from Stuart Mossman and moved the factory from Winfield Kansas to Dallas Texas. For the next five years Scott built around 250 Mossman guitars all with his proprietary bracing. These guitars are currently sought after for their superior sound when compared with other Mossman models with his earlier bracing design. It was during this time Scott built custom guitars for many known artists including: Donovan, Greg Lake, John Mellancamp, Joe Walsh (2 guitars), Jorma Kaukonen, BJ Thomas, Dave Alvin, Ray Wylie Hubbard, Will Sexton, Carl Perkins, James Burton and Willie Nelson. In 1986 Scott built two custom Farm Aid guitars for Farm Aid 3 in Lincoln Nebraska one of which went to Willie and the other went to the Hard Rock Cafe.

In 1992 Scott went to work for the Denver Folklore Center where he established their repair shop. Here Scott did repairs and restorations while also building a few new custom guitars. During this time Scott worked with Ramblin Jack Elliot among others.

In 1999 Scott started the Colfax Guitar Shop in Denver where he specialized in repairs, restorations, and making new hand made custom guitars.

Around 2001 Scott’s son, John who was 18 at the time, came to work under Scott to learn lutherie work.

He currently builds some of the most beautiful and highly sought after guitars in the world in Durango Colorado under the name of JC Baxendale Guitars. His guitars are sold through Mass Street Music In Lawrence Kansas. Music legend Mark O’Conner plays his guitars exclusively.

At the time Scott had several broken used old Harmony acoustic guitars laying around in the shop that we had collected over the previous years. As a teaching tool Scott and John decided to take these guitars completely apart and then rebuild them. The idea behind this is that in the context of one guitar you are covering several of the most important bases when it comes to mastering luthier repair skills. These necessary skills include a neck reset, plane and refret, making a new bridge, nut and saddle, crack repairs, seam repairs, fret dressing, action adjustments and mastering the neck angle, bridge thickness and saddle height relationships. Each guitar rebuild covers all of these skills so through the process of rebuilding multiple guitars a student eventually masters these skills by learning hands on through repetition.

The original Harmony and Kay guitars had crude ladder bracing which only had one purpose and that was to the keep the guitar from being pulled apart by the string tension. There was no consideration as to how the guitar was going to sound with this bracing design. This style of crude ladder bracing gives a thin tone with very little harmonic overtones. Our proprietary bracing is designed to maximize the tone and sound while still providing necessary structural support. This advanced bracing design transforms the sound of the guitar from a simple thin sounding tone with very little overtones to a tone that is full of rich harmonics and good volume with incredible balance and loads of headroom.

As Scott was teaching his son through this process of rebuilding these guitars we decided that since the guitar was already taken apart then why not go ahead and replace the bracing with our advanced bracing design that was going into Scott’s custom guitars. It seemed like a fairly easy extra step to dramatically improve the sound of the guitar.

The end result exceeded our expectations because the newly rebuilt guitar sounded better than anything else in the shop. We hung it on the wall and less than 2 weeks later someone came in and bought it. We kept on rebuilding these guitars and as my son’s skills improved so did the rebuilt guitars and everyone of them sold easily because of how amazing they sounded and how cool they looked.

At the same time other guitar builders and factories were beginning to make new guitars with the faux relic look while we were doing the exact opposite by remanufacturing real relic’d guitars with all new internal structure.

This began our journey of using the Baxendale Conversion Process as our method to teach students how to repair and restore guitars at a high level. Most of our former students are currently making all or part of their living doing luthier work based on our training through the rebuilding of these instruments.

In 2025 Scott and his Baxendale Luthier Academy is now taking on new students who are interested in learning from Scott’s 50 plus years experience in the professional luthier business.

In Scott’s 6 month luthier training course students will learn the craft and skills of guitar making and repair through learning Scott’s proprietary trade marked process of guitar remanufacturing.

More Information

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

About the Business

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.